WhatsApp)

WhatsApp)

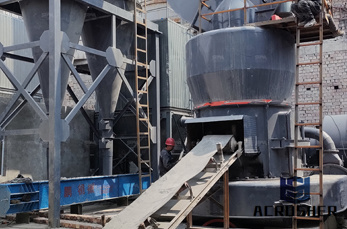

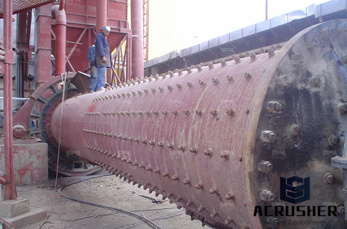

grinding mills ball mills. ... A ball mill is a cylindrical device used in grinding ... and is widely used in production of powders such as cement, silicates, ...

volume ratio of grinding ball in ball mill. ... 02. grinding volume calculation in a ball mill. sbm china product grinding for cement mill circulating load ratio ball .

Ball mill is the main equipment of ore dressing process, and it is widely used in mining, metallurgy, building materials, refractory, cement, chemical and thermal ...

Grinding Media Ratio In Cement Mill % of grinding media in ball mills for both chambers ... grinding media distribution chart of both chamber cement ball mill ...

volume of ball in ball mill. ... Request for feedback for a Two Chamber Cement Mill Ball Chge ... ball filling ratio, and mill rotation speed on energy efficiency of ...

The principle of Grate Discharge grinding is nearly universally adapted in the cement grinding industry. Grate Discharge Ball Mills are the rule rather than the ...

Overview. The ball mill for clinker is an efficient tool for fine powder grinding. It is mainly used to grind the clinker and raw materials in cement industry and ...

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory ...

what is the ld ratio in ball mill ... cement grinding mill Cement clinker is usually ground using a cement ball mill. Speed ratio Φ ≤25 15 ...

be applied in cement grinding optimisation. Only the cement clinker grinding ... reduction ratio . F0 optimum ... grinding plant is the twocompartment ball mill,

calculation in filling ratio for ball mill ; About Our Company; Quick Quote ... This method only gives a rough and initial idea for sizing a cement ball mill. ...

Lime Slaking Westpro Machinery Lime Slaking. ... slaker developed from the reliable and robust proven in service Westpro attrition scrubber, or in a ball mill type ...

Design and Optimization of Ball Mill for Clinker Grinding in Cement ... For commercial cement plant ball mill 12 ... quantify ball mill design parametersto reduce ...

What Is The L%2fd Ratio In A Ball Mill; ... Cement Mill Cement Ball Mill Ball Mill In Cement Plant; What Of Copper Is In The Ore Before And After The Mill;

Cement Ball Mill. Cement in powder form can be changed from plasticity paste to hard stonelike body and can become a total cemented granular materials through ...

The power consumption and steel consumption of the ball grinding mill occupy a rather high cost ratio in the production and processing process of a cement plant.

Optimization of mill performance by using online. previously, at a mill stop, the measurement of ball charge filling degree could beof the charge.

The grinding ratio of cement mill can reach more than 300, and it is easy to adjust the fineness of the final products. ... Ball mill has strong adaptability to ...

Ball Mill From China Zenith. This page is about the zenith Ball Mill for silicate, cement, ceramic,chemical fertilizer.

... and all modern cement ... water/cement ratio ... Raw Material Grinding Mill. 1. Mixing ratio of ... grinding ball loading to the mill;

HeNan Yu Hui can supply any type of ball mill machine, If you are interested in our ball mill,cone ball mills, EnergySaving Ball Mill,welcome to contact us.

Optimization of Cement Grinding Operation in ... in combination with a ball mill), ... baghouse involves capital expenditure with a high benefit to cost ratio.

Introduction of Cement Ball Mill: ... Ball Mill,Cement Mill... lengthdiameter ratio to avoid overgrinding and achieve the best effect of grinding. 3.

Cement grinding Vertical roller mills versus ball ... get a cement quality that is similar to the quality of cement ground in a ball mill. ... the ratio between mill ...

WhatsApp)

WhatsApp)