WhatsApp)

WhatsApp)

Highperformance grinding For many applications Hammer mills for many ... The Optimill series consists of hammer mills for raw material grinding of normal to coarse

Raw Material Grinding Mill, Wholesale Various High Quality Raw Material Grinding Mill Products from Global Raw Material Grinding Mill Suppliers and Raw Material ...

cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal ...

The ATOX Raw Mill is a highly efficient mill that grinds all types of raw materials – saving both space and energy while delivering outstanding performance

A rawmill is the equipment used to grind raw materials into ... occasionally called vertical spindle mills. In a typical arrangement, the material is fed onto ...

Mill (grinding) Wikipedia, the free encyclopedia. A grinding mill is a unit operation designed to break a solid material into smaller pieces. There are many ...

raw material grinding cement industry – CGM Mine Machine . Ball grinding mill, roller grinding mill for slag, coal, fly . Alternative raw materials (ARM) like ...

Raw material mill products are mainly used for grinding of cement raw materials, also applies to the metallurgical, chemical, electric power and other industrial and ...

MVR roller mill Gebr Pfeiffer SE grinding raw material mill,throughput rate, up to 1400 t/h mill drive, up to 12000 kW number of grinding rollers, up to 6 feed ...

Raw Materials. A paint is composed of pigments, solvents, resins, and various additives. The pigments give the paint color; solvents make it easier to apply; resins ...

Raw material mill is the key equipment that smashes materials which have already been broken by crushers and been mixed. It is mainly used to grind various materials ...

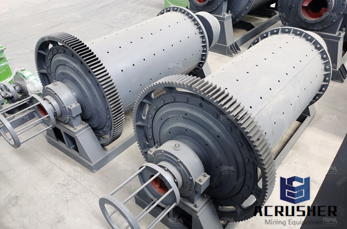

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

CEMENT RAW MATERIALS PLANT SIZES. The coordinates of the grinding table diameter and number of rollers can be read off from the table. The x .

Raw Mill,Raw Material Ball Mill ore processing. The Raw Mill, also called raw material ball mill is key equipment for the grinding process of the raw material .

Overview. This ball mill is mainly used for grinding raw materials and final products in cement plant. It can be replaced by vertical raw mill. It is also suitable ...

raw material grinding mill m_ATOX raw mill FL The marketleading .3 Many applications, many adaptations The ATOX raw mill has demonstrated its suitability for ...

Tube Mill for sale,cement ball mill,raw material grinding mill. ... Cement grinding mill is mainly used in grinding cement raw materials and finished products, ...

Raw Materials Mill, Wholesale Various High Quality Raw Materials Mill Products from Global Raw Materials Mill Suppliers and Raw Materials Mill Factory,Importer ...

raw material grinding mill. Global Law and Regulation MOFCOM. Various Bonded grinding wheel with its diameter no more than 400 Open dicofol production technique ...

... ground to a fine powder in horizontal mills similar to those used for grinding the raw materials. ... in mills that grind raw materials for the ceramic and ...

About Cement Carolinas Cement Company. We transfer the mixture into a rotating kiln where the raw materials become partially, As the mill rotates, the grinding ...

Raw material preparation with integrated blending bed, direct mill feeding system Raymond Grinding Mill. The right mixture is crucial Requirementoriented blending ...

Windmill raw materials design. There are two classes of windmill, horizontal axis and vertical axis. The vertical axis design was popular during the early development ...

Raw mill is mainly used in grinding raw materials and final products in cement plant. It is also suitable for grinding various ores and other materials in the ...

WhatsApp)

WhatsApp)