WhatsApp)

WhatsApp)

This paper reports a part of an ongoing laboratory investigation in which the compressive strength of ground granulated blastfurnace slag (GGBFS) concrete studied ...

Application and Research of Wetgunning Based on Colloidal silica for Main trough of Blast Furnace Chiong Chen* Sunward Refractories Co., Ltd.

wet blast furnace slag. Material Safety Data Sheet – Lafarge in North America. Blast furnace slag granulation at cast house.

A Study on Durability of Blast Furnace Slag Cement Concrete Mixed With MetakaolinBased Artificial Pozzolan in Actual Marine Environment Kohei Eguchi1, Koji Takewaka1

After the sample of blast furnace slag was decomposed completely by hot dilute nitric acid and hydrofluoric acid,three portions of this test solution were ...

Blast Furnace Slag 45 As mentioned earlier, the reactivity of slag depends upon the glass content. The finer grains of granulated slag are rich in glass.

12/8/2015 Blast Furnace Slag, Essar Steel Algoma Inc. Page 1 of 7 Safety Data Sheet (SDS) Section 1: Identification 1 (a) Product Identifier: Blast Furnace Slag

Waste slag as alternative raw material in the cement ... Steel furnace slag is cooled similarly to air ... Typical chemical properties of blast furnace slag.

Blast Furnace Slag Material Description ORIGIN In the production of iron, iron ore, iron scrap, and fluxes (limestone and/or dolomite) are charged into a blast ...

Slag is the glasslike byproduct left over after a desired metal has been separated (, smelted) from its raw ore. Slag is usually a mixture of metal oxides and ...

Groundgranulated blastfurnace slag (GGBS or GGBFS) is obtained by quenching molten iron slag (a byproduct of iron and steelmaking) from a blast furnace in water ...

1. INTRODUCTION Being a coproduct of iron manufacture in a modern blast furnace, molten blast furnace slag can be processed to produce a variety manufactured products1

Read "Wet and dry cured compressive strength of concrete containing ground granulated blastfurnace slag, Building and Environment" on DeepDyve, the largest online ...

... while the other two are blends of Portland cement and slag only. Blast furnace ... the use of ground granulated blast furnace slag as a ... The wet process kilns ...

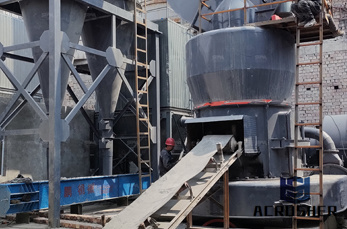

Blast Furnace Process and cost optimization from a single source Primetals Technologies offers a complete portfolio of blast furnace technologies and knowhow ...

Dry Granulation of Blast Furnace Slag for Heat Recovery. About 300 kg of molten slag are the byproduct from one ton hot metal produced at integrated iron and steel ...

The effects of slag content and polymerbinder ratio on the properties of autoclaved and combined wet/drycured polymermodified mortars using ground granulated

Flight Dynamics and Sensible Heat Recovery of Granulated Blast Furnace Slag Lianyong Wang1, Wenqiang Sun*,1, Xiaoling Li2 and Jiuju Cai1

ii Crystallization of Blast Furnace Slags Pertaining to Heat Recovery Shaghayegh Esfani Doctorate Materials Science and Engineering University of Toronto

Experience has shown that the dust content of the gases leaving a blast furnace ... the slag and metals in the furnace ... the wet cleaning of blastfurnace gas ...

3 Iron Unit Recycling ... Blast furnace slag has a relatively low iron content and finds almost complete ... (yielding blast furnace flue dust) followed by a wet

SAFETY DATA SHEET: GROUND GRANULATED BLAST FURNACE SLAG REVISION DATE: 7/22/15 PAGE 4 Product: Ground granulated blast furnace slag LD50/LC50

On Nov 7, 2013 Markus Kofler (and others) published: 316787 Dry Granulation of Blast Furnace Slag for Heat Recovery

Material Safety Data Sheet For . Ground Granulated Blast Furnace Slag . DURA SLAG™ Section I – Identity

WhatsApp)

WhatsApp)