WhatsApp)

WhatsApp)

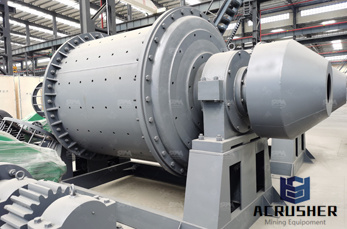

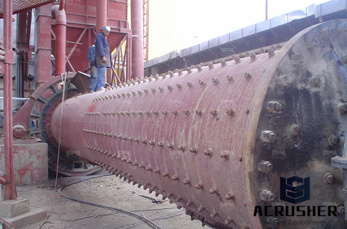

Photo of a 10 Ft diameter by 32 Ft long ball mill in a Cement Plant. Photo of a series of ball mills in a Copper Plant, grinding the ore for flotation.

Know More ... Ball Mills, Ball Milling Equipment British Rema Ball Mills are used for the particle size reduction of a wide variety of materials In a range of sizes ...

Planetary Ball MillS 4 applications RETSCH Planetary Ball Mills pulverize and mix soft, mediumhard to extremely hard, brittle and fibrous materials.

The Glassware Gallery: Ball Milling. An introduction to particle size reduction with ball . Ball Mills. Ball mills, also known as . to 2,000 each depending on ...

FL ball mill for cement grinding. ... The FL ball mill is designed for ... Mill diameter Mill diameter 5 3 2 3 2 3 1 3

Ball End Mills have a hemispherical tip used to machine rounded details, such as the metal bearing grooves found in machines. Also called Ball Nose End Mills, they ...

program gives as output the calculated mill length, mill diameter, mill speed, ball load, hydrocyclone number and the size distribution in all of the circuit

Mill diameter refers to the cutting diameter of the tool. ... Ball end mills, also known as ball nose end mills, are used for milling contoured surfaces, ...

Ball mill. A typical type of fine grinder is the ball mill. ... P 80 is the mill circuit product size in micrometers; F 80 is the mill circuit feed size in micrometers.

The Emax is an entirely new type of ball mill for high energy input. Ball Mills; Cutting Mills; ... A ball mill for powerful size reduction and homogenization.

Ball charges: This calculator ... Ball top size ... This calculator analyses the granulometry of the material inside the mill and proposes a modification of the ...

Oct 21, 2016· Now chatting: Contact Us: Grinding media sorting and balls Magotteauxin a mill.

Ball Mill Presentation Free download as PDF File (.pdf) or read online for free. My presentaion on Ball Mill Cairo University Faculty of Engineering Chemical ...

diameter cylinder length cylinder ... milling 65% of critical DRY Working ... Ball Mill Capacity Dimensions Author: jhoffmann

The optimal ball diameter in a mill 331 In accordance with Eq. 2, the necessary condition for grain comminution is:

The specific rates of breakage of particles in a tumbling ball mill are described by the equation S i = ax α i (Q(z), where Q(z) is the probability function which ...

The optimal ball diameter in a mill. grinding quartz and copper ore in a laboratory ball mill, there has been defined a general form of the equation for determining ...

More balls with small size results in fine powder. As a thumb rule powder to be milled should be taken as 25% of total ball weight. If the quantity of charge is very ...

Our combined experience in ball mill design and process ... Particle size reduction of materials in a ball mill with the presence of ... Steel Ball Mills.

Ball mill rpm calculation on size – Ball mill rpm calculation on size. Gulin supply Mining and construction equipment for mineral handling.

Talk with the Experts at Paul O. Abbe about your process requirements and Size Reduction and Dry Milling Equipment.

Machinery and Equipment buys and sell Used Ball Mills for mining and minerals applications, ... Allis Chalmers Svedala ball mill, 13'' diameter x 21'' long, ...

A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls ...

Ball end mills are used for drilling shallow holes, ... A ball end mill will produce a radius one half the diameter of of the tool used.

WhatsApp)

WhatsApp)