WhatsApp)

WhatsApp)

HIVECTOLHVI (PDF format, 2224kBytes) steel rolling mills, supplies AC drive systems ... mill power converters, dump truck drives for mining ..... drives but also for rotary kiln drives in the cement. Read more

Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement. The mill may operate in either open or closed circuit and with or ...

ABSTRACT In cement plants, proper specification and supply of AC induction motors is critical to project schedules and providing efficient production. This paper focuses on the selection of AC induction motors for cement mill

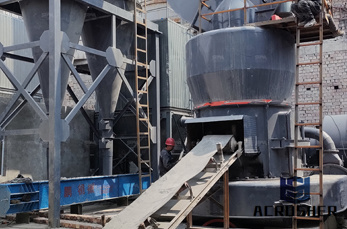

THE MVR MILL FOR CEMENT GRINDING OPERATION RESULTS OF BALAJI PLANT Bernd Henrich*, Dr. Caroline Woywadt* * Gebr. Pfeiffer SE, Kaiserslautern, Germany 1. Brief introduction With the introduction of the MVR mill for ...

A typical process of manufacture consists of three stages: grinding a mixture of limestone and clay or shale to make a fine "rawmix" (see Rawmill); heating the rawmix to sintering temperature (up to 1450 C) in a cement kiln; grinding ...

what is cement mill main drive cement mill main drive – Grinding Mill China speed of cement mill drive. speed of cement mill drive ® Crusher Heavy Industry(shanghai) is the best speed of cement mill drive manufacturers and ...

The regression model was based on artificial neural networks for predicting the electricity consumption of the mill''s main drive and evaluating established ... A cement mill is the equipment used to grind the hard, nodular clinker from ...

Article Reprint Source: IEEE Standards Association Selecting Inching Drives for Mill and Kiln Applications Glen Cala Frank C Uherek, Principal Engineer Gear Engineering Software Development Abstract The inching drive, also ...

Customer: Cement plant From an African cement plant Menzel received the order to supply a interchangeable motor to the existing main mill drive. In fact the customer bought already another interchangeable Menzel ...

coal raw mill motors coal raw mill motors Grinding Mill China . fineness x power motor vertical raw mill Cement Ball Mill; ... main drive motor for vertical raw millCGM Machinery . Get Price

TecoWestinghouse Motor Company Custom Motors DC spherical seat bearings utilized on TECOWestinghouse Motor Company DC motors are designed for main rolls ... Vertical Grinding Mill Zenith NZ Center Drive Thickener ...

Operational Experience from the United States'''' First Vertical ... Separator drive Mill outlet Mill feed inlet ... FIGURE 4 shows the cement mill production both immediately after ... One of the main focus points regarding cement VRM » Learn More

ABB''s Gearless mill drive system is the most powerful mill drive system in the market to power semiautogenous (SAG), ball and autogenous (AG) mills Home ...

Cement Mill Description of EnergySaving Cement Mill According to the type, ball mill can be latticetype and overflow type; according to the characteristics, ball mill can be wet mill, dry mill, automatic mill and semiautomatic mill. ...

Cement Kilns: Firing systems Firing systems for cement kilns ... The firing floor of Wilmington kilns 3 (further away) and 4, around 1920. Get Price Online Eddie''s Portable Chain Saw Mill the Ladder . Click here for Page two the ...

FL ball mill for cement grinding Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or moist ... Cement Process Chemistry SlideShare · About Cement ...

Galbiati Group manufactures main and auxiliary gear drives for mills and kilns for cement industry. Galbiati Group recently implemented a main gear drive for mills and kilns addressed to the cement industry with a rigid electrowelded ...

Special Gearboxes Sector Shanthi Gears Cement. Ball Mill Drive, Bevel Helical Vertical Gear Box for Air Separator, Helical and Bevel Helical Rolling Mill, Main Hoist Planetary Gear Box, Pinion Online Or Get Price

OTHER INDUSTRIES PeakVue Technology Detects Damaged Bearing and Keeps Cement Mill Running RESULTS • Saved 460,000 (USD) in lost production. • Saved 50,000 in repair parts and labor. • Avoided emergency shutdown.

High Torque Planetary Gears PBLZ The Drive System Design Complete package of equipment 3 Main Gear / Coupling: 14 18 rpm 4 Cement Mill 5 Oil System, optional ... Compact and Efficient main drive of Rotary Kilns 21 May ...

Changsha Aobo Carbon Co., Ltd. Carbon Brush, Metal Carbon Brush, Morgan Carbon Brush for Generator Parts manufacturer / supplier in China, offering China supplier carbon brush CH17 for cement mill main drive 561 MD1 ...

complete set of cement machinerycement millroty Tube mill/Ball mill/Cement mill/Coal mill/Sl... vertical mill/roller press/grinding equipment Product of Crusher Series Dust collector/environment equipment... Used and new cement ...

One (1) Used Dry Process Cement Plant, Clinker Capacity 1200 tpd Main equipment includes: Polysius Impact Crusher, 220kW, 70 tph Hazemag Impact Crusher, 2x160kW, 50 tph Loesche Vertical Raw Mill, 1000kW, 80100 tph

residue on 212 µm. The specific power consumption for mill main drive and classifier drive at shaft is warranted with kWh/t. 5. Final remarks Since 2007 several MVR mills and Multi Drive® for grinding cement, cementitious ...

WhatsApp)

WhatsApp)