WhatsApp)

WhatsApp)

The specific rates of breakage of particles in a tumbling ball mill are described by the equation S i = ax α i (Q(z), where Q(z) is the probability function which ...

Simulation of Size Reduction in Ball Mills and DEM. By Luís Marcelo Tavares on 03 Mar 2015. ... which are just about the coarsest size present in the mill, ...

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

Grinding Media is used to finely grind ore material to a size which allows recovery of the desired ... Planetary Ball Mill; Laboratory Jet Mill; Electric Mortar ...

Ball Mill Loading Dry Milling. Ball Mill Loading (dry milling) When charging a ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar use on a jar ...

Our combined experience in ball mill design and process equipment development totals more than 60 years and allows us to put a unique spin on steel and lined mills.

ball mill ball size. The effect of ball size on mill performance,ScienceDirect. The specific rates of breakage of particles in a tumbling ball mill are described by ...

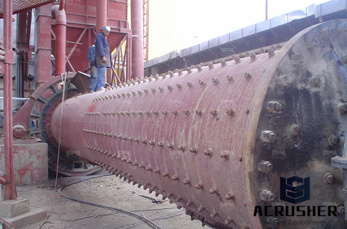

Ball mill is the most commonly used grinding equipment. It is widely used in cement, silicate products, new building materials, refractory, fertilizer, nonferrous ...

What is ball milling? A ball mill is a type of grinder used to grind materials ... Major parameters for ball milling Temperature Size and Number of the balls

Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement.

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

THEORETICAL CALCULATION OF MILL STEEL BALL SIZE: DUAN XIXIANG: OreDressing Section, Kunming Institute of Technology, Kunming 650093, PRC

Ball Size In Ball Mill, Wholesale Various High Quality Ball Size In Ball Mill Products from Global Ball Size In Ball Mill Suppliers and Ball Size In Ball Mill Factory ...

Size Ball Mill, Wholesale Various High Quality Size Ball Mill Products from Global Size Ball Mill Suppliers and Size Ball Mill Factory,Importer,Exporter at

A grinding circuit simulation combined with ball weal law was used to determine the optimum composition of the makeup ball sizes in tumbling ball mills.

The optimal ball diameter in a mill 331 In accordance with Eq. 2, the necessary condition for grain comminution is:

Find great deals on eBay for Ball Grinding Mill in Metalworking End Mills. Shop with confidence.

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill ...

Ball mill rpm calculation on size – Ball mill rpm calculation on size. Gulin supply Mining and construction equipment for mineral handling.

Martin Chick Associates CNC ... Resources. Speed And Feed Calculators Ball Mill Finish Calculator Part Spacing Calculator G And M Code Characters Standard End Mill ...

Planetary Ball Mills are used wherever the highest degree of fineness is required. In addition to wellproven mixing and size reduction processes, these mills also ...

How to Choose Suitable Ball Size of Ball Mill Source: clirik By Ammy Posted: . Ball Mill is key equipment of regrinding material after it crushed.

Grinding in Ball Mills: Modeling and Process Control ... The design of a ball mill can vary significantly depending on ... The size of a mill is usually characterized ...

EMAX High Energy Ball Mill Retsch. The Emax is an entirely new type of ball mill for high energy milling. ... The novel size reduction mechanism of the E max ...

WhatsApp)

WhatsApp)