WhatsApp)

WhatsApp)

CEMENT MILLING: PROCESS MODELING ... Ball Mill Cyclones Weight Feeders ... calculated from the model process value, yexp is the

model of the ball nose end milling process, using ABAQUS Explicit to demonstrate the highspeed machining of Inconel 718 superalloy. In this work, Ball nose end mill ...

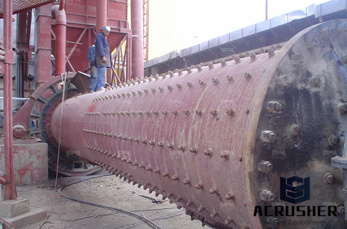

Ball Milling Process Introduction: The ball mill is the key milling machine to break and to smash materials. It also is an effective tool for many materials ground ...

TY JOUR. T1 Mechanistic modeling of the ball end milling process for multiaxis machining of freeform surfaces. AU Zhu,Rixin. AU Kapoor,Shiv G.

Zhu R, Kapoor SG, DeVor RE. Mechanistic Modeling of the Ball End Milling Process for MultiAxis Machining of FreeForm Surfaces. ASME. J. Manuf.

Due to the development of CNC machining centers and automatic programming software, the ballend milling have become the most widely used machining process for ...

Fig. 1 Schematic model of microball end milling operation Table 2 Ti–6Al–4V material parameters for JC model A ... Modeling of burr formation process

CEMENT GRINDING OPTIMISATION ... The process is designed and operated ... The basis for modeling the twocompartment ball mill is the perfect mixing ball mill model.

Union Process offers a full line of high quality grinding media balls, engineered to meet your most demanding milling applications.

Ball mills designed for long life and minimum maintenance overflow ball mill sizes range from 5 ft. x 8 ft. with 75 HP to 30 ... process engineering and ...

Contributions to the modelling of the milling process in a planetary ball mill 23 ing impact energy in their study, and they focus on inspecting the collision between ...

Modeling of Turnmilling Process Abstract ... develop a process model for turnmilling operations. In this article, for the first time, uncut

ball milling model. ball milling process model[crusher for sale] The Simulation Analysis for the Milling Process of Ball End, It is difficut to analyze the ball end ...

What is a Ball Mill? A ball mill is a type of grinding mill, purposed similarly to the sag mill or other mining crushers. These machines are used to grind or mix ...

Numerical simulation of milling process needs an accurate model of cutting tool. In this paper, we describe the methodology developed to design flat and ball end ...

Dry milling and fractionation of grain ... The dry milling process includes a number of ... which can even be an appropriate substitution for hammer mill and ball ...

ball milling process: Topics by ... Bij Cumulative breakage function ....Here the ball mill model, bmmex2, is fed ... Chat Now!

Union Process manufactures a broad line of standardsetting wet and dry grinding Attritors and small media mills, and offers a wide assortment of grinding media

... kinematics of ball end milling process in ... of ball end milling process. The proposed model ... Mechanics and Dynamics of Ball End Milling ...

Sand Ball Mill Process ... This mill is recommended for wet grinding only Model 01 The Model 01 is the most basic model in the 01 ...

Synthesis of Nanomaterials by High Energy Ball Milling W. Cao . Skyspring Nanomaterials, Inc., wcao It is a ball milling process ...

What is ball milling? A ball mill is a type of grinder used to grind materials into extremely fine powder. 7 . Major parameters for ball milling ... process Tip of

Modelling and simulation of ball mill wear. ... during this grinding process, ball mill element wear affects ... it was possible to model and then to simulate ball ...

tion and condition monitoring 2 Tubeball mill mathematical model for ... Based on a dynamical model of the grinding process in closed circuit mills,, Ball Mill ...

WhatsApp)

WhatsApp)