WhatsApp)

WhatsApp)

Read "A novel method for modelling of interactions between pulp, charge and mill structure in tumbling mills, Minerals Engineering" on DeepDyve, the largest online rental service for scholarly research with thousands of academic ...

2012/04/26· Two and ThreeDimensional Simulation of Ball and Rock Charge Motion in Large Tumbling Mills R. K. Rajamani; B. K. Mishra; A. Joshi; and J. Park Download Tools Download Citation Add to Favorites Track Citations ...

SAG Mill Efficiency,Energy efficiency of Tumbling Mills The energy efficiency of tumbling mills can be examined directly by looking at the motion of ore and grinding balls inside the mill. The makeup of the charge and the ...

2011/01/27· The two dimensional motion of the individual balls in a tumbling ball mill was analyzed numerically by a Distinct Element Method using the extended Kelvin model composed of nonlinear spring and nonlinear dashpot. A ...

DOI / Discrete element modelling of lifter stresses in tumbling mill N. Djordjevic consumed in impact type breakage as the number of lifters increases within a mill of given size. Results also show ...

Town ONLINE SENSORS FOR MEASURING THE TOTAL BALL AND CHARGE LEVEL IN TUMBLING MILLS by SARPONG BISMARK DONKOR BSc. Mineral Engineering, University of Mines and Technology TarkwaGhana, 2009.

Motion Analysis in Tumbling Mills by the Discrete Element Methodt mill, which is the genesis of the forces experi enced by the particles to be ground. Motion analysis of the charge of particulate material in a tumbling mill was... » Get Quote

International Journal of Mineral Processing, 40 ( 1994 ) 171186 Elsevier Science, Amsterdam 171 Simulation of charge motion in ball mills. Part 1: experimental verifications Mishra and Raj K. Rajamani ...

8th European LSDYNA Users Conference, Strasbourg May 2011 SIMULATION OF CHARGE AND STRUCTURE BEHAVIOUR IN A TUMBLING MILL Pär Jonsén 1, Bertil I. Pålsson 2, HansÅke Häggblad 1, Kent Tano 3, Andreas ...

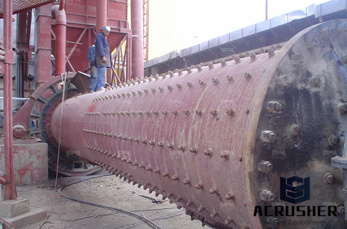

Tumbling mills: In this mill, the mill shell is rotated and motion is imparted to the charge via the mill shell. The grinding medium may be steel rods, balls, or rock itself. Tumbling mills are typically employed in the mineral industry for ...

TY JOUR T1 Motion Analysis in Tumbling Mills by the Discrete Element Method AU Mishra,B. K. AU Rajamani,R. K. PY 1990 Y1 1990 N2 The media motion in a ball mill is simulated using a numerical algorithm known ...

Mechanics of media motion in tumbling mills with.The charge motion in Motion Of Charge In Tumbling Mill a tumbling mill is analyzed in detail using a numerical simulation scheme known as the discrete element method (DEM). In ...

83 Centrifugal force outward Fc mp 2 Dm 2 () is the angular velocity, mp is the mass of any particle (media or charge) in the mill and Dm is the diameter of the mill inside the liners. Gravitational force Fg mpg () The ...

376 HJ. Steiner /ht. J. Miner. Process. 4445 (1996) 373382 Fig. 1. (I) Actual motion of a mill charge. (II) Equilibrium surface of the mill charge according to Barth (1930). (III) The ultimate stage of abstraction ...

3 Grinding process Reducing particle size distribution Tumbling mill High power demand Breakage by impact, chipping and abrasion Influenced by size and mineralogy Control product size by medium, speed of rotation and charge ...

Two and Threedimensional Simulation of Ball and Rock Charge Motion in Large Tumbling Mills R. K. Rajamani, 1 B. K. Mishra, z A. Joshi, 1 J. Park 3 Introduction The mining industry routinely uses ball mills and ...

The dynamics of charge motion in tumbling mills has been a challenging problem both experimentally and theoretically. The harsh environment within the mill precluded sophisticated sensors. On the other hand, first principle 10 ...

SME 2013 Abstract Understanding mill charge motion is important. In the charge, the centre of gravity is shifted from the rotational centre of the mill system, and its motion is induced by rotation of the mill, while at the same time the ...

2017/06/27· [Show abstract] [Hide abstract] ABSTRACT: The discrete element method models the motion of charge in tumbling mills using the physics of individual collision between balls, rock particles, and mill shell. Thus it differs ...

Many authors have highlighted in previously published papers that the ore breakage is closely linked to the ball charge motion. It is well known that ball milling efficiency varies during the lifetime of the shell liner. For instance, the mill ...

motion of chargein aball mill motion of chargein aball mill. motion of chargein aball mill. As a leading global manufacturer of motion of chargein aball mill, we offer advanced, reasonable ... » Learn More motion of chargein aball mill ...

motion of charge in tumbling mill milling machinery for sale in turkey made in china raymond mills loesche rolller mill dia 96 namibian company that produces hammer mills virtical sand mill prices of feed mill and hammer grinder ...

2016/07/30· The effects of ball charge fraction and mill speed on the impact velocity of balls estimated were also discussed.

It can be concluded that the model simulation developed in the present study predicts approximately the actual ...

Tumbling ball mills are a common comminution device in the mineral industry processing, wherein the particle size reduction is performed by action of the grinding media. Different forms of transverse motion in a rotating cylinder have ...

WhatsApp)

WhatsApp)