WhatsApp)

WhatsApp)

Cement manufacturing: components of a cement plant This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement ...

Vibration Troubleshooting Ensures Reliable Raw, Vibration Troubleshooting Ensures Reliable Raw Mill Fan''s Operation Industry: Raw material extraction and processing Customer The customer is a leading cement manufacturer in ...

The key word is quality! And this quality is achieved during cement production with exactly matched process steps. ... Cement Production: Raw Meal Production in Steps Perfectly mixed, accurately fed without pulsation, and ...

Raw Mill Process, Wholesale Various High Quality Raw Mill Process Products from Global Raw Mill Process Suppliers and Raw Mill Process Factory,Importer,Exporter at MENU MENU Get the App ...

electrostatic precipitators (ESP) that follow the raw mill is returned to the process, these devices are considered to be production machines as well as pollution control devices. Additional thermal efficiencies and productivity gains have ...

THE CEMENT MANUFACTURING PROCESS quarry raw grinding and burning grinding, storage, packing, dispatch HOW TO USE THIS PRESENTATION : > once the animation has finished, click anywhere on the screen to move on

Nov 16, 2011· Process in vertical raw mill ... This feature is not available right now. Please try again later. Wood Chipper,MultiUtility Wood Chipper and Shredder ... Rajkumar Agro Engineers Pvt. Ltd. is one of the leading Indian ...

Manufacturing process < All about Cement < Cement :. Manufacturing process < All about Cement < Cement : Lafarge Lafarge, ore) are generally extracted from limestone rock, chalk, clayey schist or clay. They are then crushed ...

grinding process in raw mill, Grinding trends in the cement industry Cement Lime Gypsum Summary: The main trends concerning grinding processes in the cement industry . In the case of new orders, vertical mills have increased ...

Laos 2 Water Layout of one Japanese cement factory Waste tire yard Coal yard Electrostatic Precipitator Raw mill crusher SP calciner Rotary kiln Cement silo Shipping pier Birdeye View of Japanese Cement Factory

Raw Mill In Cement Plant,Cement Making Plant Crusher Machine This is achieved in a cement raw mill. The grinding process is controlled to obtain a powder ... Cement Manufacturing Process Rotary Kiln, Limestone Grinding ... In cement manufacturing process ...

Ash Grove Cement and Related Materials (Manufacturing Process) Ash Grove Cement and Related Materials (Manufacturing Process), Portland cements are hydraulic cements composed primarily of hydraulic calcium silicat » Learn More

Cement report DRRC Lawrence Berkeley National Laboratory Diagram of the cement manufacture process at a modern cement plant . .... The raw mill exists to grind and blend the raw materials to prepare them for the kiln.

Jaypee Group | Businesses | CementManufacturing Process The cement manufacturing process starts from, The hot gasses coming from the clinkerisation section are used in the raw mill for drying and transport of the . Read More

cement manufacturing process crusher to paking Cement Manufacturing Process | Phases | Flow Chart | Cement .Aug 30, 2012 . Cement Manufacturing Process Phase 1: Raw Material Extraction . large size rocks are crushed into ...

Jaypee Group Businesses CementManufacturing Process The cement manufacturing process starts from the mining of line, which is ... The LS Crushers crush the line to minus 80 mm size and discharge the ... the reclaimers and ...

The production process for cement consists of drying, grinding and mixing limestone and additives like bauxite and iron ore into a powder known as "raw meal". The raw meal is then heated and burned in a preheater and kiln and then ...

Cement Manufacturing Process Phases Production of cement completes after passing of raw materials from the following six phases. These are; Raw material extraction/ Quarry Grinding, Proportioning and Blending Preheater Phase

The clinker manufacturing process Al badia. The clinker manufacturing process starts with the extraction of the raw meal from the homogenization silo to insure that the raw meal is stable and homogenized Get Price

Raw material mill products are mainly used for grinding of cement raw materials, also applies to the metallurgical, chemical, electric power and other industrial and mining enterprises for grinding all kinds of ore and other grindable ...

Tenaris manufactures a complete range of seamless and welded steel tubular products. Seamless pipe manufacturing Our seamless pipe manufacturing process involves the following steps: Transformation of raw materials into steel ...

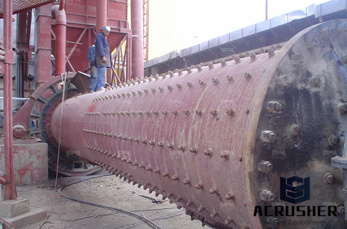

Raw Mill In Cement Plant A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. It''s mainly used in grinding raw materials and end products in cement plant. Raw mill is made up ...

Cement kilns in Belarus Arnika Association website The views expressed in this report are those of the authors and not initial production step in Portland cement manufacturing is raw materials acquisition. In the wet process, water ...

Gypsum Manufacturing Environmental Protection Agency Raw gypsum ore is processed into a variety of products such as a portland cement additive, soil conditioner, industrial and building plasters, and gypsum wallboard. ...

WhatsApp)

WhatsApp)