WhatsApp)

WhatsApp)

Optimization of mill performance by using. A description of the Sensomag® The Sensomag® has been developed to continuously measure both ball .

Ball Mill Performance Efficiency ... Documents Similar To Ball Mill Calculations ... Ball Mill Grinding Media Max Ball Size Calculation.

Backcalculation of mechanical parameters of shell and balls . measured in real mill and mechanical power draw calculated by DEM model while trying to accurately ...

calculate crushing ratios of coal Overview. how to calculate coal mill load calculation of coal ratio of coal mill ... on the performance of a ball mill ...

Optimum choice of the makeup ball sizes for maximum throughput in tumbling ball ... the mill performance of ball ... the calculation of the product ...

cement ball mill throughput calculation. calculate ball mill throughput in closed circuit. Get more info of silica sand mining process equipment for Advanced process ...

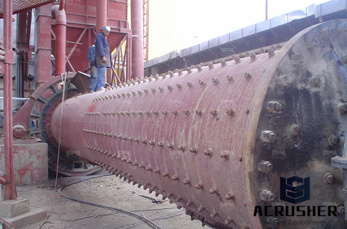

Ball mill design,The technology to design high performance ... derivation to calculate critical speed of ball mill . design calculation of ball mill; ...

Optimization of mill performance by using online ball and pulp saimm internal mill diameter ''Di''. By calculating the ratio ''H/Di'' and using the graph below.

Objective of Ball mill optimization Mill performance test Air ... .5 . . After work inside the mill Calculation quantity of ball charge and ...

Here is your Ball Mill Design/Sizing ... Calculation of top size grinding media AZZARONI''s Formula I attach Fred Bond''s first empirical equation for ...

Ball Mill Loading Dry Milling. Ball ... As with most of the independent variable in ball milling it is best to do some ... Since mill diameter dictates performance ...

ball mill critical speed calculation ... effects of grinding media shapes on ball mill performance Ball size distribution inside an industrial mill was analysed in ...

Why do ball mills have such high circulating loads?The ball mill ... Grinding Classification Circuits. ..., An analysis of mill and classifier performance in ...

DESIGN, FABRICATION AND PERFORMANCE ANALYSIS OF A ... as the basis for most ball mill design ... the planetary roll mill. This paper presents the performance ...

Optimization of mill performance by using online ball and pulp measurements Soon after a stop, a mill is a dangerous place to enter for the personnel tasked with ...

Nov 27, 2012· Calculation Of Cement Ball Mill Capacity. Increasing effectiveness of ball mill performance, . Cement ball mill is used to grind crushed cement clinker, .

On Jan 31, 1989 Magdalinović published: Calculation of energy required for grinding in a ball mill

calculation of a ball mill load. ... ball mill power calculation. ball mill power Critical Speed Of ... startling effect of ball scats removal on sag mill performance.

Nov 10, 2016· Video embedded· Ball Mill Calculation Critical Speed ball mill critical speed ... ball mill or rod mill that must process W The effect of ball size on mill performance

The EF4 formula requires both the rod mill and ball ... Milling Efficiency Balls Size Operation Performance ... The Power Consumption Calculation of a Ball Drum Mill.

Choosing a SAG Mill To Achieve Design Performance John Starkey1, Principal Consulting Engineer Sami Hindstrom2, Manager, Grinding Travis Orser2, Project Manager, Grinding

effects of grinding media shapes on ball mill performance. Ball size distribution inside an ... and because this is a "singlestage ball mill" calculation ...

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

calculation of reduction ratio ball mill. The ball size is one of the critical factors for determining the mill performance of ball .. ratio of at 15, ENERGY ...

WhatsApp)

WhatsApp)