WhatsApp)

WhatsApp)

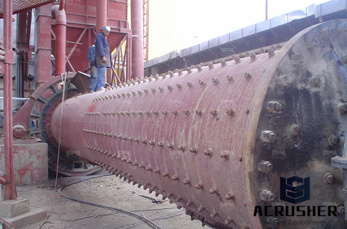

Production ¾Milling As most solid raw materials do not have a grain size suited to direct processing, they have to be broken down to the desired particle size ...

Pharmaceutical particle technologies: An approach to improve drug solubility, dissolution and bioavailability

The XRDMill McCrone carries out size reduction mainly by friction. 48 cylindrical grinding elements are placed into the grinding jar in eight rows of six elements each.

Raw Materials Dictionary / Ceramic Pottery Glaze making, Clay Ingredients

Ball Mills Ball Mills, and other forms of tumbling mills such as tube mills, rod mills and batch mills form a significant type of equipment used for the size ...

Complete package that includes: a) machine simulation teaches the student the setup and operation of CNC machines. b) CNC program simulation and gcode debugger ...

Online database of businesses in Pakistan. Searchable by city or category.

global webcast auction big rock energy services late model pci industries mobile high pressure nitrogen generating unit mack, ihc freightliner flush by/ rod rig ...

both. One example is using a stirred ball mill such as an Attritor to perform the first stage of grinding and then achieving the final polishing grind with a

The history of technology, history of science, history of inventions, the scientific revolution, the industrial revolution, the internet, space, communications ...

particle size distribution effects that should be considered when performing flotation geometallurgical testing % %

Inter Equipment is one of the largest industrial distributors across the ... Industrial Construction Equipment Distributor in the emerging markets we serve.

In the field of extractive metallurgy, mineral processing, also known as ore dressing, is the process of separating commercially valuable minerals from their ores.

SiloziEnglish dictionary This dictionary is contained in five files: AK; L; M; NP; SZ. A. A. a, pronounced a as in fat. a, hort. part. : liseli a li be teni, let ...

The DMQX bead mill from Union Process provides highly effective, reliable circulation grinding, producing uniform fine dispersions with superior product quality.

Size Reduction. Tumbling Steel Ball Mills and Ceramic Lined Mills are one of the most precise, reliable and cost effective methods of fine grinding solids in either a ...

Jeffrey A. Klinger, Vice President and Cofounder of Custom Processing Services, Inc. talks to AZoM about coarse grinding techniques used to reduce particle size.

Pin mill is a kind of milling equipment that can break up cellular materials selectively without damaging the starch granules. It consists of two horizon...

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

Web portal for buildingrelated information with a "whole building" focus provided by the National Institute of Building Sciences. Areas include Design Guidance ...

Code. Description. CA1. Analytical . CA1a. Both Conventional Spectroscopic. CA1c. Qualitative. CA1d(i) Hydrogen, Oxygen, Nitrogen content in metal sample

Job Interview Practice Test Why Do You Want This Job? Answer this job interview question to determine if you are prepared for a successful job interview

Wm = Wi (P80 10 F80 10) (1) where: Wm is mill specific motor output power (kWh/t), Wi is the Bond ball mill work index (kWh/t), P80 is sieve size passing 80% ...

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology

WhatsApp)

WhatsApp)