WhatsApp)

WhatsApp)

critical speed of ball mill formula and derivation. Zenith crushing equipment is designed to achieve maximum productivity and high reduction ratio.

The effects of mill speed and filling on the behaviour of the ... SAIMM. Feb 2, 1988 ... The dynamics of the ball load within a wetgrinding ... of critical ...

Critical Speed Of Ball Mill Formula Derivation show the critical speed of ball mill derivation,derivation for the critical speed of ball mill Calculate critical ...

TECHNICAL NOTES 8 GRINDING R P King Mineral Tech show the critical speed of ball mill derivation,The critical speed of the mill, c, is defined as the speed at ...

Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction and Mill Speed Critical Speed needs.

Critical speed analysis for nonlinear effects of rotor, The critical speed analysis for nonlinear effects of rotorbearing system and ball end milling are, The ...

Critical speed can be ... Aside from common ball mills there is a second type of ball mill called a planetary ball mill. Planetary ball mills are smaller than ...

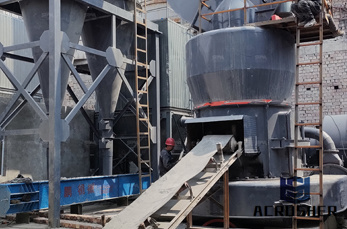

show the critical speed of ball mill derivation. Crushing Equipment. Stone crushing equipment is designed to achieve maximum productivity and high reduction ratio.

ATTRITORS AND BALL MILLS ... Eastern Training Conference and Show May 9, ... The theoretical critical speed of a ball mill is the speed at which the centrifugal force ...

show critical speed ball mill Results show that the leaving angle decreases as the mill speed ratio increases and as the radius ratiosingle steel ball is enormous ...

ball mill critical speed YouTube. Apr 22, 2015 formula to calculate critical speed in ball mill, critical speed formula for ball the speed where, mathematically ...

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

show the critical speed of ball mill mathematical. Ball Mill. Ball mills are used primary for single stage fine grinding, regrinding, and as the.... Belt Conveyor.

The Effect of Ball Size Diameter on Milling. show the critical speed of ball mill derivation A laboratory size ball mill was used with ball media of sizesm..takes ...

A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell''s inside ...

A General Model for Semiautogenous and Autogenous Milling. maximum capacity and minimum kWh/ton at about 6070 ball load at 25070 .... i=1,2, .. n.

The ball size is one of the critical factors for determining the mill performance of ball mills. ... 1 shows the typical variation of the S values with particle size ...

Show The Critical Speed Of Ball Mill Derivation. critical speed of ball mill formula and derivation... findings show that there is a ...

show critical speed of ball mill calculation (04 Jun 2012) Gulin supply Mining and construction equipment for mineral handling. The crushing, screening, Get Price.

Mill Critical Speed Determination. The "Critical Speed" for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces at ...

Ball Mill Critical Speed. ... at the condition 70% of critical speed of cement ball mill in ... 0. and show the graphical represent Figure 18 ...

show critical speed ball mill A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at ...

Bond formula for the grinding balls size calculation. Oct 19, 2017 C – the mill drum rotational speed,% of the critical speed; As practice shows, the difference ...

Planetary Ball Mill Process in Aspect of Milling Energy. speed ratio in the initial stage and then falls around the. critical speed ratio, which can be calculated ...

WhatsApp)

WhatsApp)